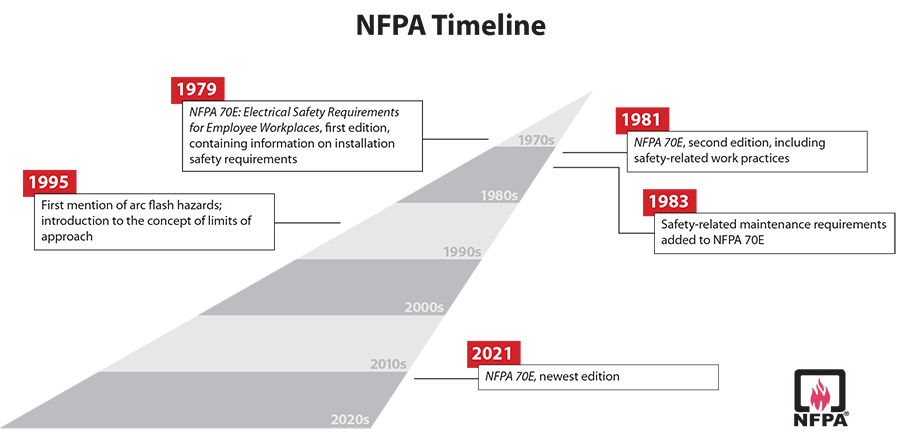

Understand how the changes to IEEE 1584 impact incident energy and arc flash boundary calculations to know if your arc flash study is still valid.

Field service technicians and maintenance workers depend on personal protective equipment (PPE) and safety policies to avoid injuries when they’re working on electrical equipment. Companies rely on recommendations from standards organizations, but they are open to interpretation. One example is the IEEE standard 1584, IEEE Guide for Performing Arc-Flash Hazard Calculations, which was released in 2002 and updated in 2018. There is some debate as to how the newest calculation recommendations impact workplace safety practices.

When it comes to low- and medium-voltage circuit breakers and electrical power distribution equipment, there are many variables that can cause arc flash hazards, including poorly maintained equipment, loose connections, dust, and dropped tools. These hazards can lead to injuries and even deaths. With stakes that high and many variables to consider, it is imperative to understand how the changes to IEEE 1584 impact incident energy (IE) and arc flash boundary (AFB) calculations to know if your arc flash study is still valid.

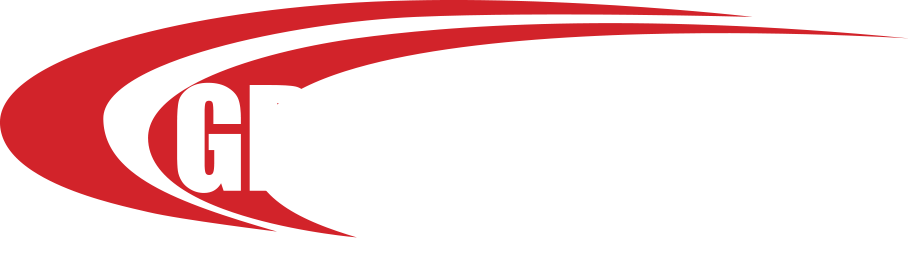

The History of Arc Flash Calculations

Many guides and standards deal with electrical components and workplace safety. Governing bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Agency (NFPA) provide outlines and practices focused on keeping workers safe around electrical equipment. IEEE 1584 is based on research from experts and other stakeholders. Though NFPA and IEEE standards are not mandated by law, companies use these documents to create safety policies.

Any changes in these standards can have significant safety and legal ramifications. For example, the updates to IEEE 1584 impact how companies ensure that their equipment and personnel are safe from arc flash incidents. While the calculations are confusing to many, the reason for the change is simple: there is more information, testing, and technology available today than when the equations were first developed.

When Ralph Lee published the first electrical hazard equations in 1981, his paper mentioned how burns from arc flash account for a substantial portion of injuries associated with electrical malfunctions. It also presented data on arc flash temperatures (including that an electrical arc can be four times hotter than the surface of the sun), how distance affects the severity of injuries, and protection methods. The report warned that molten shrapnel from metal terminals, reaching temperatures of about 1832°F, could shower the area around an arc.

This initial research provided a foundation for how to keep workers safe around electricity. Testing has continued, and today there is a greater understanding of arc flash properties and therefore a need for updated calculations.

What You Need to Know About the IEEE 1584 Updates

The PPE required for those working with electricity changes based on temperature, distance, voltage, type of current, and other factors. All stakeholders need to understand arc flash to determine the risk and the level of PPE necessary to reduce injuries and equipment damage. While research continues, significant changes in how IE and AFB are calculated include:

- A revision of voltage classifications and definitions

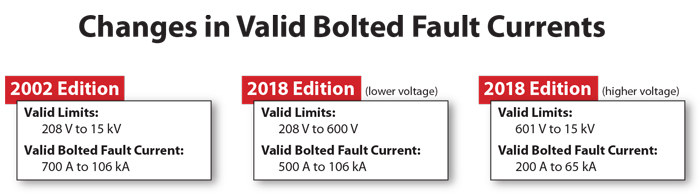

- Changes to bolted fault current levels

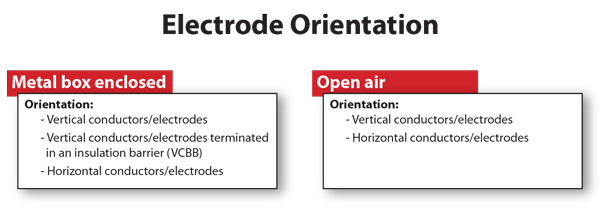

- An updated electrode configuration factor

- An enclosure-size correction factor

- Removal of the system grounding variable

- Inclusion of minimum distance

Overall, calculations are now sixth-order logarithmic equations with variable coefficients. There are still no calculations for DC systems, possibly because there is not enough scientific data to develop an accurate model. Depending on the power source, arc fault conditions can change or behave uniquely. This will lead to more testing and likely multiple models for accurate DC arc flash calculations. According to a paper on electrical injuries from the National Center for Biotechnology Information (NCBI), AC is approximately three to five times more damaging than DC of equal voltage and current. While injuries are still associated with DC arc flash, there is a difference in the statistical ROI on workplace safety.

As with the 2002 edition of IEEE 1584, guidance and recommendations for arc flash are provided for single-phase systems but are not included in the calculations. Changes in voltage classification include a new lower-voltage class for 600 V and below. Equipment operating above 600 V is considered higher voltage. The calculation changes depending on this classification.

A statement concerning voltage in low-energy systems was also added: “Sustainable arcs are possible but less likely in three-phase systems operating at 240 V nominal or less with an available short-circuit current less than 2,000 A.” Previously, equipment operating below 240 V, in addition to having other characteristics, did not require arc flash analysis. It was believed that the energy was not great enough to generate IE of more than 1.2 cal/cm2. The change to the standards may require more safety precautions for lower-voltage systems.

Some interesting discoveries altered the calculations. According to section G.7.11 of the standard on system grounding, “The IEEE/NFPA collaboration test results did not show any significant impact of the system grounding or bonding on the incident energy released by the arc.” Therefore system grounding configuration is not used as an input parameter in the 2018 edition of IEEE 1584. The updated standard also states that calculations are not valid within 12 inches of the arc source as hot plasma gases from the arc source cause inaccuracies in the model.

Perhaps one of the biggest changes is the new electrode configuration factor. The coefficients change based on electrode orientation, which can significantly alter the amount of IE to which workers are exposed. There are different orientations based on metal-enclosed and open-air equipment.

This configuration can greatly affect IE results, so it is imperative that engineers understand different bus configurations and how they can change an arc event.

Conclusion

The increased complexity of these calculations is intimidating. There is software to make arc flash calculations easier, but for workplace safety, it is imperative to find experienced engineers who understand the science. If incorrect numbers are used or a result is off, an engineer who knows only the plug and chug of the software may not catch a lifesaving change.

When it comes to keeping field service technicians and maintenance workers safe around electrical power distribution equipment, and keeping the equipment itself in proper working condition, accurately calculating arc flash hazards is necessary. Understanding how different factors of arc flash interact and affect the environment around electrical equipment can help companies create policies that keep employees and equipment safe. As organizations collaborate for more accurate safety calculations and regulations, companies must ensure that all stakeholders are protected.

Read more about how Group CBS electrical companies can help mitigate arc flash danger: