Many solar array owners assume that as long as their system is generating power, everything is running optimally. The reality is more complex. Without proper testing and maintenance, your solar power system could be underperforming — losing energy and reducing return on your investment over the system’s lifetime.

Several factors that can quietly erode the efficiency of solar panels. Weather conditions like clouds, fog, and snow obviously impact output, but many other factors fly under the radar. Dust, dirt, and grime also gradually accumulate on panel surfaces, blocking precious daylight. Environmental factors play a larger role than most realize. Reflections from nearby buildings, water, or even parked vehicles can create uneven lighting conditions across your array. Shade from new construction or growing trees that were not an issue during installation can dramatically impact energy production later on. Over time, the protective materials on panels naturally degrade — think of how car headlights become cloudy after years of sun exposure.

Without testing, you won’t know how your system is performing. In a recent NETA World article, CBS Field Services’ Jason Carlson explored how photovoltaic (PV) array testing will continue to advance as solar power use grows.

Testing Solar Arrays

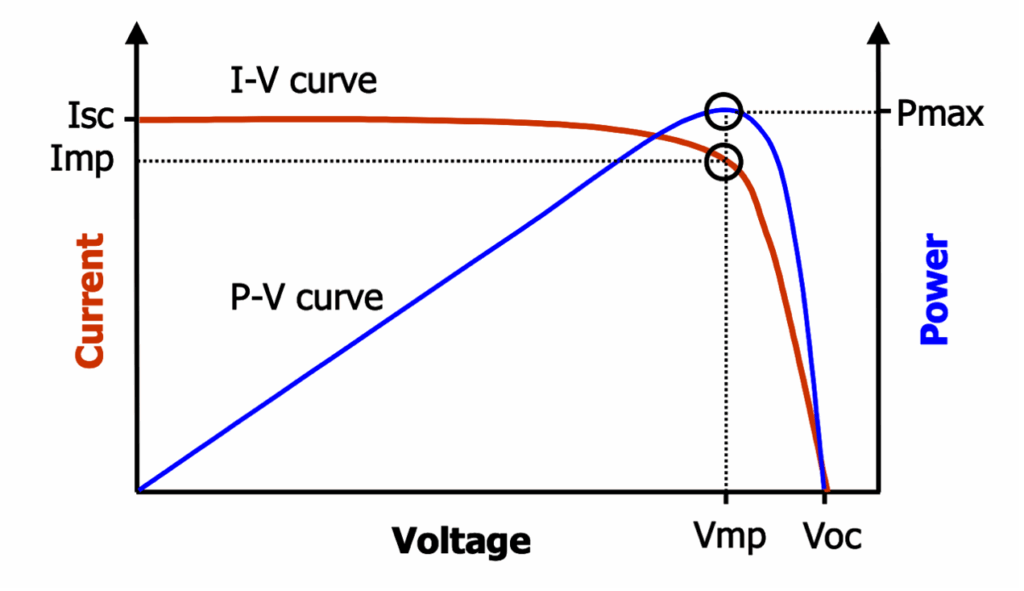

Professional solar testing centers on I-V curve analysis. This is essentially a snapshot of performance that measures how much current and voltage your panels are producing under existing conditions. This test method accounts for irradiance (available sunlight), temperature, and actual electrical output to create a complete picture of your system’s health.

The “knee” of a normal I-V curve, where Imp and Vmp intersect, shows where the array generates maximum electrical power.

Proper I-V curve analysis requires specialized equipment that most property owners don’t have access to. This includes irradiance sensors to measure available light, DC clamp meters for precise current readings, infrared cameras to detect hot spots and damaged cells, and insulation resistance meters that ensure electrical safety. Advanced testing systems can compile the data needed to create detailed performance profiles.

The maximum power point, where your panels generate peak electrical output, will vary based on conditions. Professional testing determines whether your system is actually reaching this optimal point and offers insights into the factors that might be preventing it.

Timing Matters

Timing is important for solar testing. Measurements taken during suboptimal conditions, such as when the sun is low or the sky is cloudy, will not provide an accurate baseline. To ensure meaningful results, it is best to test when conditions allow for peak production.

Timing must also take ambient temperature into consideration, as higher temperatures typically reduce voltage output. Proper testing accounts for these and other variables to help determine whether performance issues stem from environmental factors or actual equipment problems.

Whether your solar array is newly installed or approaching its expected life span, knowing your system’s true performance becomes crucial for making informed decisions about maintenance, upgrades, or replacements. Regular professional testing helps you maximize your investment, identify problems before they require costly repairs, and ensure you’re capturing every kilowatt-hour of available energy.

For a deeper dive into the test methods and equipment used to optimize solar array performance, read the NETA World article here.

NETA-certified technicians from CBS Field Services provide electrical testing and maintenance services to ensure that your solar array is delivering optimal performance. For more information, to discuss your requirements, or to request an estimate or quotation, contact us.

Learn more:

-

- The Critical Moment When Troubleshooting Becomes Repair

- Emergency Support Team Restores Power to Hospital After Two Electrical Faults

- Be the Electrical Technician That Stands Out Among Others

- How to Properly Test Medium-Voltage Cables

- NFPA 70B Provides Guidance for Maintenance Based on Equipment Condition